History

Innovation and Excellence Across Generations

PHH was founded in the 1960s as a small distribution warehouse on Valencia Street in Barcelona, with a clear mission: to supply phosphates, caseinates and fibrous and cellulose casings to the food industry. From the beginning, the company has distinguished itself by its commitment to quality and its focus on meeting the specific needs of its customers.

In the 1980s, PHH marked a new milestone in its history by introducing plastic casings for the meat industry in the Spanish market, importing innovative materials from Japan. This move not only broadened the scope of its offering, but also consolidated PHH as a pioneer in the incorporation of advanced technologies into the sector.

During the 1990s, the company took another significant step by integrating the first flexographic printing machines into its factory. This development allowed PHH to diversify its services, offering customized printing solutions that added value to its customers’ products. In the 2000s, they further expanded their portfolio with the addition of laminating films, strengthening their position as a one-stop supplier for the food and meat industry.

Today, PHH is in the hands of the third generation of the founding family. This family legacy has kept alive the innovative spirit and technical approach that have always defined the company. We are proud to be a benchmark in the sector, with an eye on the future and countless projects to develop.

With decades of experience and a firm commitment to excellence, PHH continues to make a difference in the industry, guided by the innovation and dedication that have been its hallmarks from the beginning.

Our values

Our brands

Always at the forefront, PHH offers the best brands on the market

PROVEEDORA HISPANO HOLANDESA, S.A.U. has received aid for its energy savings and efficiency project titled "Energy Improvements in the Flexographic Printing System", co-financed by the European Regional Development Fund (ERDF), coordinated by IDAE and managed by the autonomous communities, under the National Energy Efficiency Fund, with the aim of achieving a cleaner and more sustainable economy.

An energy improvement project has been developed for the printing system through the implementation of an RTO system with heat recovery. Thanks to this project, an annual saving of 36.98 toe (tonnes of oil equivalent) is achieved.

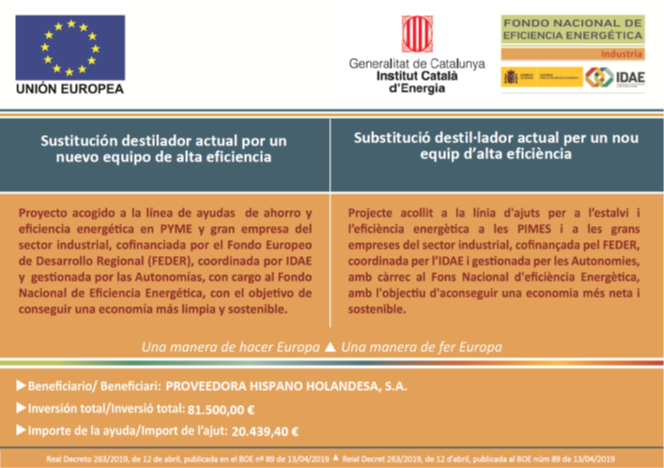

PROVEEDORA HISPANO HOLANDESA, S.A.U. has received aid for its energy saving and efficiency project “Replacement of the current distiller with a new high-efficiency unit,” co-financed by the European Regional Development Fund (ERDF), coordinated by IDAE and managed by the autonomous communities, charged to the National Energy Efficiency Fund, with the objective of achieving a cleaner and more sustainable economy.

An energy improvement project has been developed, consisting of replacing the previous distiller with a new high-efficiency one. Thanks to the project, 6.93 toe are saved annually.

With the collaboration of: